Metal Stamping Market Report 2025 Edition: Industry Size, Share, Growth and Competitor Analysis

The increasing emphasis on sustainable manufacturing practices, along with the rising adoption of metal-stamped.

BROOKLYN, NY, UNITED STATES, July 1, 2025 /EINPresswire.com/ -- IMARC Group has recently released a new research study titled “Metal Stamping Market Size, Share, Trends and Forecast Report by Material, Press Type, Process, Application, and Region, 2025-2033”, offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.Report Highlights:

How Big Is the Metal Stamping Market?

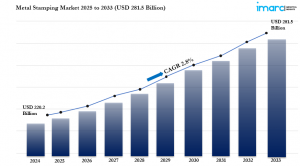

The global metal stamping market size was valued at USD 220.2 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 281.5 Billion by 2033, exhibiting a CAGR of 2.8% during 2025-2033. Asia Pacific currently dominates the market. The increasing emphasis on sustainable manufacturing practices, along with the rising adoption of metal-stamped parts in the oil and gas sector for equipment and machinery, is propelling the metal stamping market share.

Market Key Highlights:

● Market Growth: The metal stamping market is witnessing strong growth, driven by rising demand from the automotive, electronics, and aerospace industries.

● Target Demographics: Primarily used by manufacturers seeking precision-engineered components for high-volume production processes.

● Product Variety: Includes blanking, embossing, bending, coining, and flanging processes tailored for sheet metal fabrication.

● Industrial Trends: Increasing automation and adoption of progressive die stamping are enhancing production speed and consistency.

● Distribution Channels: Distributed through OEMs, contract manufacturers, industrial suppliers, and online procurement platforms for global reach.

Request to Get the Sample Report: https://www.imarcgroup.com/metal-stamping-market/requestsample

5G in the Metal Stamping Market Trends

The arrival of 5G technology is poised to revolutionize the metal stamping industry by significantly improving connectivity, automation, and real-time data capabilities. By 2025, the ultra-fast speeds and low latency offered by 5G networks will allow manufacturers to implement real-time monitoring, control, and optimization of stamping operations across smart factory environments.

With 5G, manufacturers can seamlessly integrate IoT-enabled devices, enabling continuous communication between machines, sensors, and operators. This level of connectivity will empower companies to gather actionable insights on production metrics, machine health, and quality parameters. In turn, it will support predictive maintenance strategies, minimizing equipment downtime and reducing operational disruptions.

Moreover, 5G will accelerate the transition to fully automated, responsive production environments. Smart stamping systems will be able to dynamically adapt to shifting production demands, enhance efficiency, and reduce waste. As the industry embraces this digital transformation, 5G will act as a foundational enabler of innovation and productivity, reshaping the future of metal stamping through smarter, faster, and more agile operations.

Market Dynamics of the Metal Stamping Market & Demand

● Rising Demand from the Automotive Sector

The automotive industry continues to be a major growth driver for the metal stamping market. As automakers invest in advanced vehicle designs and shift toward electric and hybrid models, there is an increasing need for lightweight, durable, and precisely engineered metal parts. By 2025, this demand will escalate as manufacturers aim to improve fuel efficiency and meet stringent emissions regulations.

Metal stamping provides a cost-effective solution for producing large volumes of high-quality parts like body panels, chassis components, and battery enclosures. The push for automation in automotive manufacturing is further increasing the adoption of stamping technologies, enhancing both production speed and accuracy. As EVs and next-gen vehicles become mainstream, the role of metal stamping in supplying essential structural components will only grow stronger, solidifying its position as a core element of the automotive supply chain.

● Technological Advancements and Industry 4.0 Adoption

The integration of Industry 4.0 technologies is fundamentally reshaping the metal stamping market. By 2025, manufacturers are expected to leverage smart systems, including IoT sensors, AI-driven analytics, and advanced robotics, to boost productivity and streamline operations. These technologies enable precise, real-time monitoring of equipment performance, defect detection, and process optimization.

Automation and digitalization are also making stamping operations more scalable and efficient, reducing human error and enhancing product consistency. Advanced techniques like progressive die stamping and deep drawing are enabling the creation of complex geometries and tight-tolerance components. As innovation accelerates, companies that adopt digital manufacturing technologies will gain a competitive edge through increased output, reduced waste, and improved quality, driving overall market growth.

● Expanding Applications in Electronics and Consumer Goods

Beyond the automotive sector, the metal stamping market is gaining traction in electronics and consumer goods manufacturing. As devices become more compact and technologically advanced, demand is growing for miniature, intricately stamped components such as casings, connectors, and heat sinks. By 2025, the surge in smart devices, IoT applications, and wearable technology will continue to drive this trend.

Simultaneously, consumer preferences are shifting toward customization and fast product cycles, requiring more flexible, high-precision manufacturing processes. Metal stamping offers an ideal solution for producing small-batch, detailed components with minimal lead time. Manufacturers are investing in agile stamping technologies to meet the dynamic requirements of these sectors. This diversification of end-use applications will further fuel the growth of the metal stamping market in the years ahead.

Checkout Now: https://www.imarcgroup.com/checkout?id=2152&method=1670

Metal Stamping Market Report Segmentation:

Breakup By Material:

● Steel

● Aluminum

● Copper

● Others

Steel account for the majority of shares due to its strength, durability, and cost-effectiveness.

Breakup By Press Type:

● Mechanical Press

● Hydraulic Press

● Servo Press

Mechanical press dominates the market as they offer high speed and efficiency for high-volume production runs.

Breakup By Process:

● Blanking

● Embossing

● Bending

● Coining

● Deep Drawing

● Flanging

● Others

Blanking represents the majority of shares due to its fundamental role in creating flat components from sheet metal.

Breakup By Application:

● Automotive

● Industrial Machinery

● Consumer Electronics

● Aerospace

● Electrical and Electronics

● Healthcare

● Defense

● Telecommunications

● Others

Automotive exhibits a clear dominance owing to the high demand for precision-engineered components essential for vehicle manufacturing.

Breakup By Region:

● North America

● Europe

● Asia Pacific

● Latin America

● Middle East and Africa

Asia Pacific holds the leading position owing to a large market for metal stamping driven by rapid industrialization, urbanization, and a booming automotive sector.

Top Metal Stamping Market Leaders:

The metal stamping market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

● Acro Metal Stamping

● American Axle & Manufacturing Inc.

● American Industrial Company

● Arconic Corporation

● Aro Metal Stamping Company Inc.

● Caparo Engineering India Limited

● CIE Automotive

● Clow Stamping Company Inc.

● D&H Industries (Vista Equity Partners)

● Goshen Stamping LLC

● Interplex Industries Inc. (Amtek Engineering)

● Kenmode Precision Metal Stamping

● Klesk Metal Stamping Inc.

● Tempco Manufacturing Company Inc.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=2152&flag=C

Key Highlights of the Report:

● Market Performance (2019-2024)

● Market Outlook (2025-2033)

● Market Trends

● Market Drivers and Success Factors

● Impact of COVID-19

● Value Chain Analysis

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Elena Anderson

IMARC Services Private Limited

+1 631-791-1145

email us here

Distribution channels: Business & Economy, Chemical Industry, Companies

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release